Advance Metallurgical Private Limited- NABL Accredited Laboratory

Rockwell Cum Brinel Hardness Testing service

120.00 INR/Unit

Product Details:

X

Rockwell Cum Brinel Hardness Testing service Price And Quantity

- 120.00 INR/Unit

- 1 Unit

Rockwell Cum Brinel Hardness Testing service Trade Information

- Gujarat

- Cash Advance (CA)

- 50 Unit Per Week

- 2 Days

- No

- Contact us for information regarding our sample policy

- Standard Packing

- Rajasthan, Sikkim, Tamil Nadu, Tripura, Uttar Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Telangana, Pondicherry, Uttarakhand, West Bengal, All India, West India, North India, Lakshadweep, Mizoram, Meghalaya, Andhra Pradesh, Dadra and Nagar Haveli, South India, Central India, East India, Gujarat, Karnataka, Kerala, Manipur

- ISO/IEC 170525 : 2017

Product Description

WE are one of the leading service provider of Rockwell Cum Brinel Hardness Testing service . We provide 99% accuracy assured for all of our tests.Features :

Fully automatic operation for Rockwell & Brinell.

Motorized system for applying and removing of load.

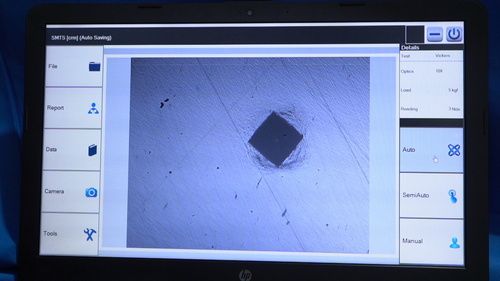

Sophisticated controller with high definition touch screen center.

Optical depth measuring system for Rockwell.

High end video based hardness testing firmware, including CCD camera, automatic indent measurement, high definition optical magnification of indent system.

Password and user level access system. Easy calibration system.

High / Low - Ok / not ok tolerance indication for hardness valves.

Automatic weight selection by thumb wheel.

Huge data storage capacity.

USB port for data transfer to computer.

Inbuilt pendrive for data backup.

Statistical report and analysis.

Load range Rockwell 60,100,150 Kgf.

Load range Brinell 187.5, 250 Kgf.

Conform to IS : 3804, BS-891, ASTM-E-18.

Motorized system for applying and removing of load.

Sophisticated controller with high definition touch screen center.

Optical depth measuring system for Rockwell.

High end video based hardness testing firmware, including CCD camera, automatic indent measurement, high definition optical magnification of indent system.

Password and user level access system. Easy calibration system.

High / Low - Ok / not ok tolerance indication for hardness valves.

Automatic weight selection by thumb wheel.

Huge data storage capacity.

USB port for data transfer to computer.

Inbuilt pendrive for data backup.

Statistical report and analysis.

Load range Rockwell 60,100,150 Kgf.

Load range Brinell 187.5, 250 Kgf.

Conform to IS : 3804, BS-891, ASTM-E-18.

Comprehensive Hardness Testing

Our service covers both Rockwell and Brinell hardness measurement techniques, adaptable to various metals. With certified calibration and compliance to key standards, clients receive reliable and repeatable findings every time. The system supports multiple indenter types to suit different material requirements.

Wide Load Range and Test Capability

Designed to cope with diverse specimen sizes and loads, our hardness tester accommodates a load range from 10 kgf to 3000 kgf. It can support larger workpieces with a maximum height of 220 mm and a throat depth reaching 133 mm.

Accuracy and Certified Calibration

Precision is assured with accuracy that meets IS:1586 and IS:2281 standards. Each test is backed by certified calibration, providing traceable and dependable results for quality assurance.

FAQs of Rockwell Cum Brinel Hardness Testing service:

Q: How is the hardness test performed using this service?

A: The hardness test is conducted by applying a precise test load, ranging from 10 kgf to 3000 kgf, with either a diamond or ball indenter. The indentation depth or size is then measured using an analog dial gauge for accurate results.Q: What types of materials can be tested with this equipment?

A: This Rockwell cum Brinell tester is suitable for metals and alloys, accommodating various material hardness measurement needs in industrial and laboratory settings.Q: When should I choose this hardness testing service?

A: This service is ideal when you require certified, standard-compliant hardness analysis for quality control, materials investigation, or routine checks on metallic components.Q: Where is the testing service available in India?

A: The service can be availed at the providers facilities in India, ensuring convenient access for industries across major cities and regions.Q: What is the process followed for calibration and accuracy assurance?

A: Calibrations are performed according to IS:1586/IS:2281 standards, with certification provided for each test. This guarantees traceability and reliable accuracy throughout the testing process.Q: How does the readout system work for hardness measurement?

A: The testing system utilizes a manual analog dial gauge. After the indenter creates an impression on the test piece, the dial gauge displays the hardness value directly for easy interpretation.Q: What benefits do clients gain from using certified hardness testing?

A: Certified hardness testing ensures precise, repeatable, and traceable results, supporting regulatory compliance and informed material selection or product verification.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email